OUR

PROJECTS

PROJECT: REPLACE DRAGLINE TUB WEAR PLATES

Equipment: Marion 8750

RMS Employee numbers: 28

OVERVIEW

Richglen Maintenance Services were engaged to remove and replace Dragline tub wear plates. Once all the tub plates were welded out, some further crack repairs in the revolving frame were completed during the shutdown.

HIGHLIGHT

No accidents or incidents. The shutdown was complete ahead of time reducing the submitted budget.

PROJECT: SHOVEL RAIL & ROLLER OVERHAUL

Equipment: P&H 4100

RMS Employee numbers: 32

OVERVIEW

Richglen Maintenance Services assisted in a breakdown of Shovel 1 at Rolleston Coal Mine. Works completed were engaged in a breakdown situation which included the removal and replacement of the damaged upper and lower rail and rollers. Extensive crack repairs were also completed on the car body and revolving frame.

HIGHLIGHT

No accidents or incidents. Richglen’s team approach is reflective in the excellent safety and quality of the work completed.

PROJECT: BE2570 BOOM LOWER / RAISE

Equipment: Bucyrus-Erie 2570W

RMS Employee numbers: 16

OVERVIEW

Richglen Maintenance Services were engaged to change out the main suspension ropes as well as other opportunistic work such as boom repairs also completed during the shutdown.

HIGHLIGHT

No accidents or incidents The shutdown was complete quicker than the submitted budget, this was achieved by a combined team approach. This team approach is reflective in the excellent safety and quality of the work complete.

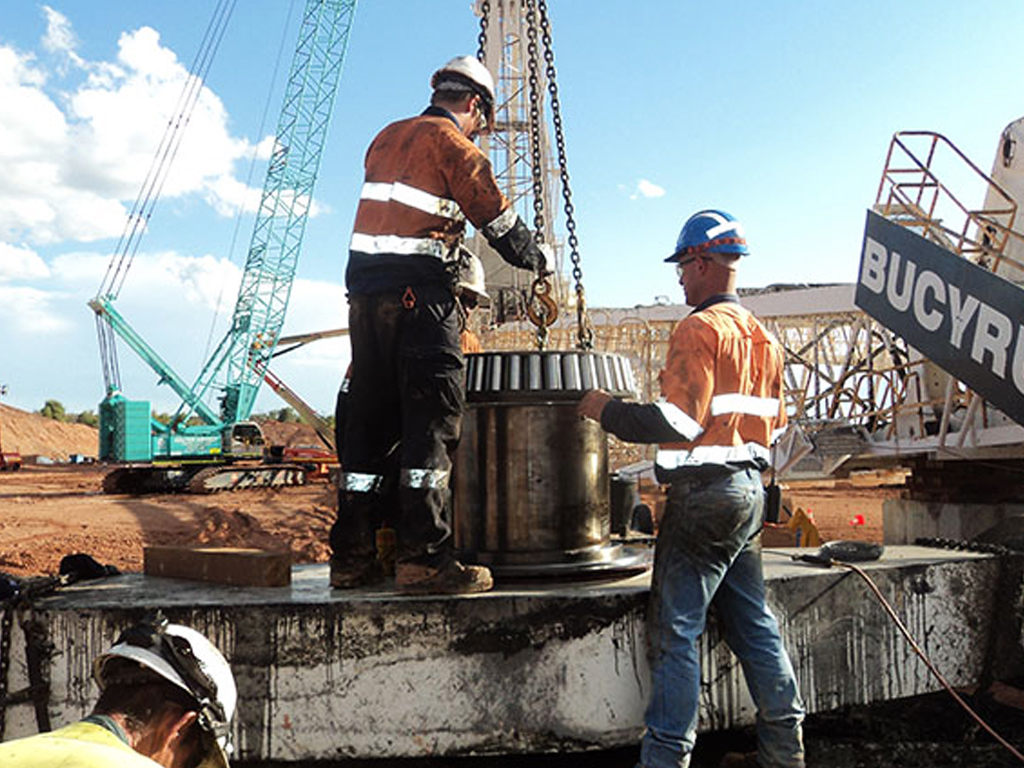

PROJECT: DRAGLINE MAINTENANCE SHUTDOWN

Equipment: Marion 8750

OVERVIEW

Richglen Maintenance Services were engage to complete a 5 day outage on Dragline 304 at Curragh Mine. The scope of work completed on the outage was the overhaul of two propel final drive pinions, carrier pins were machined.

HIGHLIGHT

No accidents or incidents Through investigation it was found that a new final drive assemble was made up of modified shaft to accommodate a larger bearing on the inboard side. This modification reduced the distance between the centres of the two bearing carrier which in turn did not fit the existing machine lugs. The larger inboard bearing was removed, site management had a spacer fabricated to bring the modified shaft back to standard.

PROJECT: MAIN SUSPENSION ROPE CHANGE OUT

Equipment: Marion 8750

OVERVIEW

Richglen Maintenance Services were engage to change out the main suspension ropes. Other opportunistic work such as boom point sheave overhauls during the shutdown.

HIGHLIGHT

No accidents or incidents. The shutdown was completed within the submitted budget which was achieved by a combined team approach. This team approach again is reflective in the excellent safety and quality of the work complete.

TO ENSURE THE SAFETY OF OUR PEOPLE IS OUR FIRST PRIORITY.